Our service begins with precision mold development. Leveraging an experienced engineering team and advanced digital design, we ensure every mold delivers exceptional stability, long service life, and high production efficiency, laying a solid foundation for high-quality die casting.

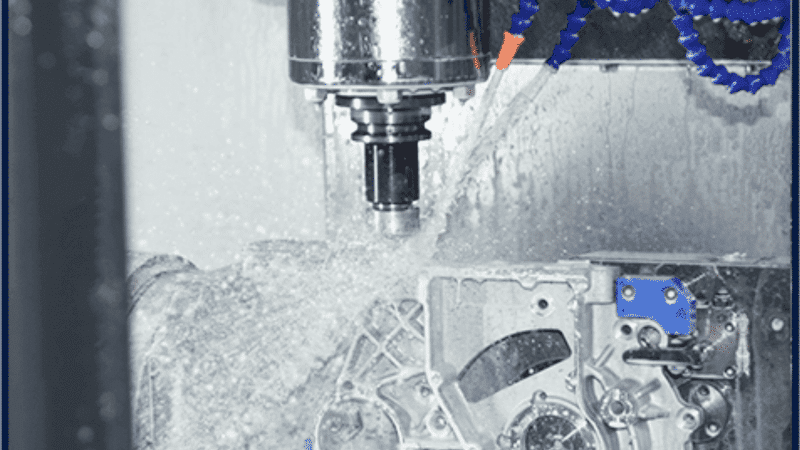

We offer comprehensive CNC machining services. Utilizing high-precision machine tools, we perform drilling, tapping, and milling on castings to achieve critical dimensions and tight geometrical tolerances, meeting your requirements for direct assembly.

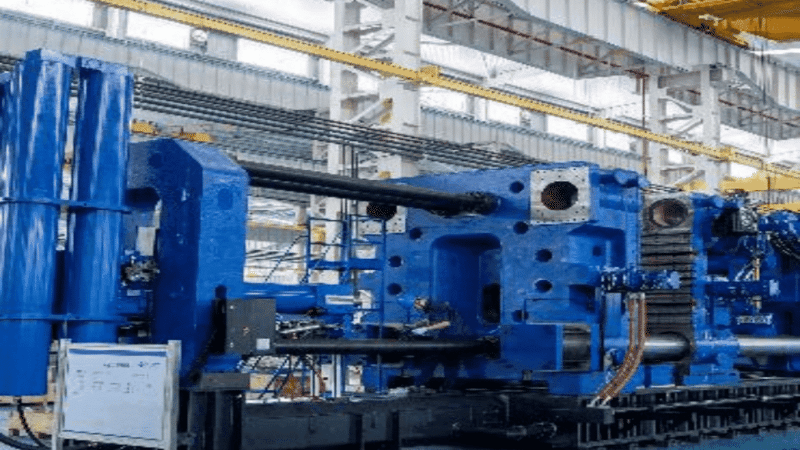

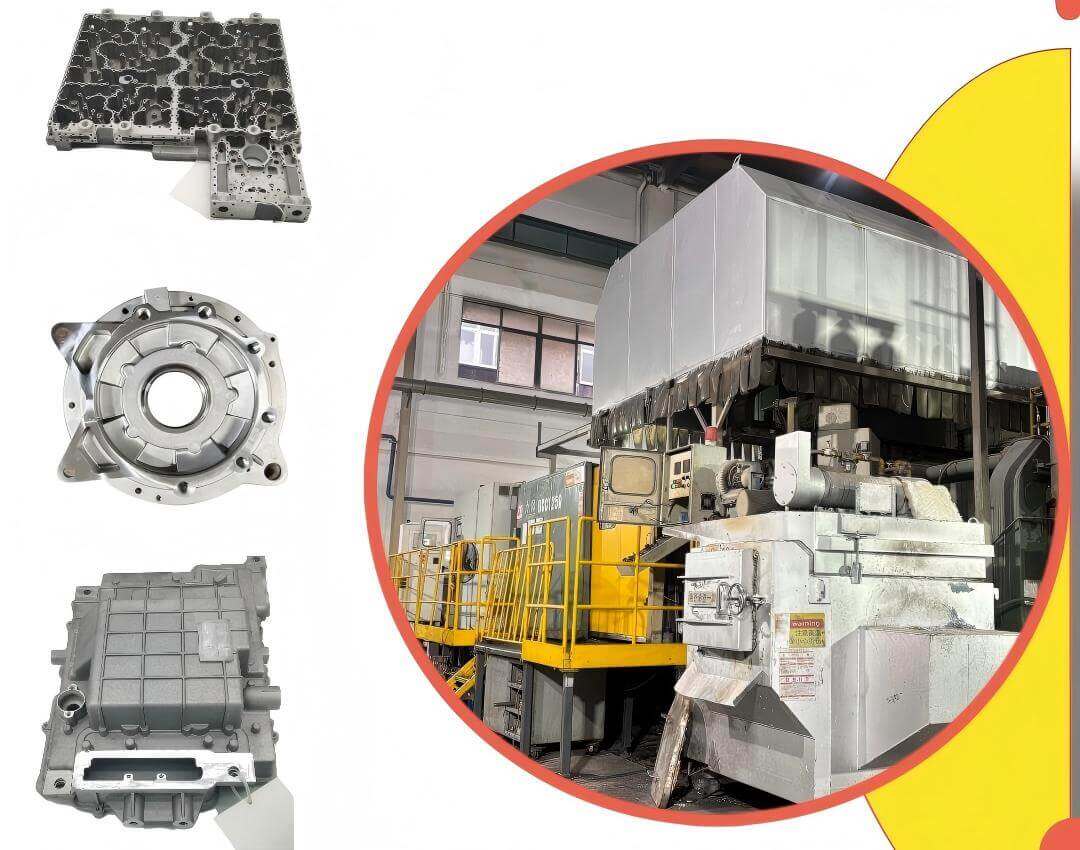

As our core process, high-pressure die casting enables us to rapidly produce large volumes of complex, thin-walled, and high-strength aluminum parts. Excellent surface finish and internal density minimize the need for secondary operations.

We master the advanced Semi-solid Thixoforming process for magnesium alloys. This lower-temperature technique produces lightweight parts with an exceptional strength-to-weight ratio, superior dimensional stability, and excellent air tightness, ideal for premium applications.

We provide a range of mechanical surface treatment processes to ensure our castings meet the highest standards of quality and functionality. Our services include expert deburring to remove sharp edges, shot blasting to enhance surface strength and uniformity, and sand blasting to achieve the desired surface texture. These treatments are essential for improving part appearance, ensuring operational safety, and creating an ideal substrate for any subsequent finishing steps, delivering components that are both reliable and ready for use.

From concept to mass production, we provide end-to-end manufacturing services for aluminum die cast parts. For any industry, we leverage mature processes and strict quality control to deliver cost-effective components tailored to your specific application needs.

Copyright © 2025 NINGBO JINYAO MACHINERY Co. LTD.